| Model: | 65MM silicon cable line |

|---|---|

| Min. Order: | 1 Set/Sets |

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

| Means of Transport: | Ocean |

| Production Capacity: | 10 sets per month |

| Packing: | export standard... | Delivery Date: | 60 days |

|---|

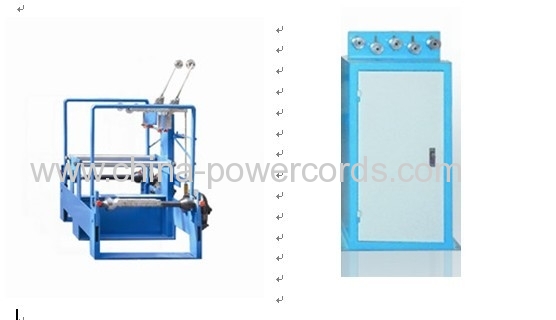

Φ65 silicone rubber extruder line

Ⅰ, the machine components are as follows:

No | Item | Quantity | application |

1 | Φ400—Φ630mm dual head tension pay-off | 1 set | Pay off wire |

2 | Straighting platform (with tool kit) | 1 set | Straighten wire |

3 | Φ65 silicone rubber extruder | 1 set | Extrude plastic |

4 | Laser Diameter tester | 1 set | Test wire dia |

5 | High speed printer | 1 set | Print letter |

6 | Electric appliances , temperature control cabinet | 1 suit | Control process |

7 | 16m vulcanization bake box | 1 suit | Vulcanizate wire |

8 | 600mm Double wheel capstan | 1 set | Tract wire |

9 | 9m horizontal tension wire accumulator | 1 suit | Accumulate wire |

10 | 15KV high frequency sparker | 1 set | Test wire quality |

11 | Electric meter counter | 1 suit | Count meter |

12 | 400-630mm Double spool take-up machine | 1 suit | Take up wire |

13 | Spare parts | 1 suit | |

14 | Tool | 1 suit | |

15 | Machine data | 1 suit |

Ⅱ.application:the machine is suitable for extruding silicon rubber cable, easy to operate, high reliable.

Ⅲ component brand:

Motor:Siemens motor

Inverter :Japanese YASKAWA inverter

Temperature controller: RKC, PID type

Electric apparatus:Schneider

PLC: Siemens color set

Ⅳ.Main specifications and performance

1. finished OD: φ1.0-φ8.0mm

2. Extrusion output: 70kg/h, the machine cross head is open.

3. Wire speed: it is according to the wire diameter V.max≤200m/min

4. Center height of machine: it is from the ground.

5. Power supply: , 50HZ,76.5KW

6. Color:cabinet use white.others use light blue, or based on customer request.

V. The main technical parameters and configuration

1.430-630MM dual head tension pay-off

1-1.suitable bobbin diameter:400-630mm , shaft through type

1-2.pay-off tension:eccentric structure adjust tension automatically,machine stop automatically when wire breaks,

1-3.brake disc:220mm

1-4.pay-off dimension:700mm*1400mm*400mm

1-5.pay-off roller: 600mm*40mm, surface is plated by hard chromium

1-6.pay-off pulley wheel:80mm ceramic wheels.

2. Straighting platform

2-1.wheel:there are 5 wheels and 3 troughs , wheel diameter: , hard chromium plated surface.

2-2.dimension: it is assembled and welded with the steel plate.

3. ¢65 silicone rubber extruder

3-1. frame:welded with A3 steel and H steel

3-2.gear deceleration box:it is modeled on the Italian 173-10

A. the square gearbox is cast formed with annealing treatment, and the material is

B. the tooth surface of gears is high-frequency quenched and polished accurately , the noise index is less than 75db, the gears are lubricated with the oil force.

3-3. Screw : one piece of silicon rubber screw of φ65mm. ,L/D of screw is 12:1,compression ratio 1.4:1) and the material is . The hardness is more than HRC82, the nitrogenization depth is , its surface is hard chromium plated; the rotational speed is10-60rpm; the extrusion capacity is 70kg/h (Max) (cross head is open).

3-4. Screw barrel: it is one-piece type from the gearbox junction to the machine head. Double layer structure. Circulating water cooling system temperature control material.internal layer material is ,and the hardness is more than , the nitrogenization depth is , surface hardness HRC85, outside layer water cooling structure is made of 45#steel .barrel diameter:φ65mm

3-5. cooling:screw barrel circulation water cooling

3-6. main motor drive:AC380V15KW Siemens motor +AC380V15KW Mitsubishi inverter control

3-7. feeding material:pressure structure.which is double roller squeeze automatic feeding

3-8 machine head:adopt adjustable water cool structure , material :40Cr,quenching tempering process HB260-280.vulcanize surface is plated by chrome.

4. laser diameter tester

4-1.origin:SHAGGHAI

4-2.precision:±0.003mm

4-3.range of wire diameter:0.1-20mm

4-4.control:automatically feedback-control main motor speed to ensure the setting range of wire diameter.

5. high speed printer

5-1.printing-wheel :outer diameter: ,inner diameter:¢20mm.Max width:25mm.

5-2.power: stirring (single-phase 220v25W).Max .printing speed 350m/min,printing quality are suitable for UL.CSA.VDE.JLS requirements.etc.

5-3.ink-box:stainless steel material,with 2 pieces

5-4..ink capstan-wheel ,printing on the surface of cable through the ink scraping device.

5-5.center height:1000mm

6. .electric appliances,temperature control(imported electric appliances)

6-1.total power switch 3 P380V

6-2.control power switch3 P380V

6-3.control power2 P380V

6-4.control power2 P220V

6-5.point current voltage meter

6-6.breaker

6-7.SSR smart type auto control heating

6-8.overload protection for motor

6-9.tension rack tension control and deflection inspect control

6-10.indicator light for each part and spotlight inside and outside control box

6-11.ventilator for control box

7. 16m stainless steel heat oven

7-1 .vulcanize pass structure is open type, inside layer is stainless, outside is steel board ,use asbestos insulation material to keep warm

7-2. the length of vulcanize pass is 16m, 4m/section,voltage 380v,per section 12kw.heating by electric heating tube.temperature control meter is installed on the control cabinet ,easy to operate

8. 600mm double-wheel capstan machine

8-1.machine rack:it is assembled and welded with A3 steel plate and channel steel.

8-2.capstan wheel:material:aluminum alloy ¢600mm,total in 2 pieces.

8-3.deceleration machine----------------WEIZHENG BRAND

A.type:four-shift speed governor

B.can change fast,medium,slow stalls according to the size of wire dia to suit for the extrusion use.

8-4.dragging :AC380V4KW Siemens motor with AC380V4KW Mitsubishi inverter,suitable for the extrusion application of different wire diameter.

8-5.line speed:V≤400m/min,It is coordinated action control with main motor.

8-6.dropping wire:dropping bucket device.

8-7.stainless steel seal water box, with window water wiper for one unit.

9. 9m Horizontal tension wire accumulator

9-1,Frame: assembled and welded with Steel plate

9-2.track:125mm*125mm,horizontal length:9m

9-3.Power:1HP reducing-speed motor----------------TAIWAN WANXIN BRAND

9-4.Tension:With 5Kg magnetic powder clutch------WEIZHENG Brand

9-5.wire-accumulating length:10m-200m

9-6. accumulating-wheel dia and material:aluminum alloy,

Wheel dia: Φ300mm, number of wheels:11+12 wheels

9-7.tension adjustment:tension can be adjusted by tension control-cabinet DC-24V power.the vehicle can be controlled in both ways .the meter indicates tension.synchronous device can automatically control the take-up speed to avoid overstretch or breaking on the wire.

9-8.safe device:the limit switch are laid at the front and back end.

The machine stops at the same time when wire breaking .

9-9.anticollision:compression spring

10.15KV high frequency sparker machine

10-1.application:It is applied for the pressure-resistance test under the condition of on-line movement of electric wire and cable.

10-2.range of outer diameter: 4.0-15mm

10-3.testing voltage: ,high-voltage frequency:

10-4.output indication:5 digit LED spark counter

10-5.testing room length:600mm

10-6.Max ampere:0.667mA

10-7.alarm output:LED Alarm indication.the coupled alarm and automatic-stop with coiler can be selected.

10-8.be suitable for JAPANESE,USA,EUROPEAN Standards or CHINESE Great wall certification

10-9.testing speed:1000m/min

11.electronic meter counter

11-1.electronic induction type meter-counting:anti-regressive function.

11-2.floating type meter-counting wheel:elastic contact on both sides.both meter-counting wheel and pinch roller have spring to support.can float with shake of cable,reduce the slip ,improve the precision of meter-counting.

11-3:meter-counting length: 0-999999m

11-4. precision level:0.1%

11-5.meter-counting factor :can be adjustable,can set the meter-counting factor according to different size of wire dia,material. To improve the

Meter-counting precision

.

12.400-630mm double-spool take-up machine.

12-1.suitable: 400-630mm reel style and bobbin style ,line speed v≤400m/min.

12-2.machine rack :it is assembled and welded with channel steel and A3 steel plate.

12-3.motor:AC380V2.2KW motor+ AC380V 2.2KW transducer and tension rack.with deflection detector can automatically

control take-up speed.

12-4.meter-counting :6 digit electronic meter-counting. with the feature of automatic-stop.

12-5.traversing:it is polished rod bearing type control traversing.the pitch and range of traversing can be adjustable.it is coordinated action with take-up speed.

12-6.attachment:with 2 suits of take-up bakelite-axis plate and axis clamp,and 2 suits of long and short axis are provided.

Ⅵ. Accessories:

A:tool kit--------------------------------------------------------------------1 pieces

Scissor-------------------------------------------------------------------1 piece

Hexagonal wrench--------------------------------------------------------1 suit

Screw driver--------------------------------------------------------------I suit

Monkey wrench-----------------------------------------------------------1 piece

B;spare parts:

Die ---------------------------------------------------------------2 sets

Stainless steel honeycomb board----------------------------------1 piece

Thread pin--------------------------------------------------------2 piece

Base and fix screw------------------------------------------------1 lot

Spare parts:

Crosshead heater

Machine neck heater

Barrel heater

C:data with machine

Installation drawing, circuit drawing, manual